patents filed till March 2021

R&D spend

*In the year 2020-21, our pursuit towards research resulted in 169 patents (69 in India and 100 overseas) filed, taking the total filed patents to 1294. 180 patents were granted during the year, taking IndianOil’s patent portfolio of effective patents as on March 31, 2021 to 1,165.

# Includes Capital and Revenue expenditure

Our knowledge-based indigenous centre of excellence provides innovative solutions that are qualified as patents, trademarks, copyrights, licenses. The team provides cutting-edge solutions across petroleum products and alternative energy segments. Spread across 65 acres, the campus at Faridabad has delivered key product developments and process innovations over the years. These innovations opened up new opportunities for IndianOil to secure its position in the field of advanced petroleum products and future energy needs since its inception in 1972.

Despite the challenges due to the pandemic during the year, our R&D team exhibited exemplary resilience to achieve excellence in the areas of development and commercialisation of indigenous technologies. The team is currently working on research programs that are focused in the areas of core petroleum activities like Lubricant, Refining, Petrochemicals, Differentiated Fuels, High Efficiency Lubricants and Pipeline Transportation Technology etc. In addition, R&D Centre is also carrying out activities in sunrise research areas of Alternative Energy segments like Bioenergy, Solar Energy, Hydrogen Economy, Energy Storage, Nanotechnology, Carbon Capture & Utilisation, and Battery Technologies etc.

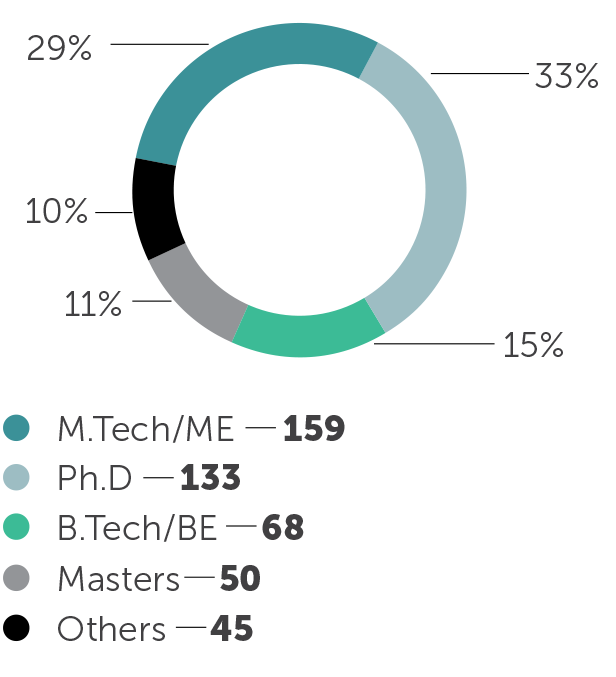

Total team size at R&D Centre

Our two PADCs at Panipat (Haryana) and Paradip (Odisha) help us keep abreast of new technology, new products/new product applications and grades. Both the centres constantly endeavour to create new petrochemical grades that meet specific customer requirements and strengthen our competitiveness.

Product Application Development Centre at Paradip

Launched in 2019, our digital transformation project, i-DRIVE, continues to make steady progress in transforming operations with innovative methods. Some of the projects have already achieved excellence in maintenance, workplace productivity, capex and operations.

Many of our customer facing applications are now enabled with AI-based chatbots for better interaction and experience. Our day-to-day operations are being further automated through robotic process automation systems. We have also introduced remote monitoring systems for predictive maintenance. Experiments are being conducted through drones and AR/VR based systems.

The Company has a comprehensive data privacy policy that complies with the IT Act and the subsequent guidelines issued by the Government of India. The Company relies on defence-in-depth approach and has deployed a series of security mechanisms to protect its data and information. The security setup covers the endpoints (PCs and servers), networks, data centres, OT set-up and all digital resources deployed across the Company. The infrastructure is supported by a 24x7, fully manned security operation centre with a central Security Incident & Event Monitoring (SIEM) and Security Orchestration, Automation, and Response (SOAR).

The Security operation Center (SOC) team constantly manages security alerts from across the organisation and provides necessary mitigation controls. We have also partnered with several cyber security bodies, such as CERT-In, NCIIPC and IB, to avert cyber-attacks.

Initiatives identified in last 2 years

As a leading energy provider, we are pursuing environment friendly and path-breaking solutions for the industry. Our in-house team focuses on emerging industry dynamics to accelerate the development of solutions that are future-ready and contribute to the mission of ‘Aatmanirbhar Bharat’.

In 2020-21, we introduced path-breaking products and process innovations that have helped us achieve superior environmental performance (consumption, emission control components) and customer experience.

IndianOil launched a high performance and best-in-class premium fuel, XP100. The high octane fuel produced by IndianOil’s refineries is a first-of-its-kind product in India that will provide unmatched mobility experience and superior vehicle performance. IndianOil’s innovative efforts have placed India among the very few advanced countries in the world that produce energy efficient fuel. The octane rating of XP100 exceeds the Bureau of Indian Standards (BIS) ratings and ensures superior combustion of engine fuel in comparison to BIS recommended gasoline.

retail outlets in the country serving XP100

During the year, digital signatures on invoices were accepted at all IndianOil stores and other operational areas. A centralised vehicle tracking and management system was also started during the year, leading to improvement in delivery time and customer satisfaction. To add efficiency to operations and enhance automation, we also upgraded our labs and introduced SMART labs.

During 2020-21, 26 marketing labs were upgraded to SMART labs and by the end of 2022-23, all 57 labs are expected to be similarly upgraded.

We have made significant progress to evaluate the use of hydrogen as a fuel for supporting future mobility. The surplus hydrogen at the Gujarat refinery would now serve dispensing facilities of fuel cell electric vehicles. Initially, this facility will be used for refuelling 25 buses operating for eight hours per day (~0.5 TPD). It will gradually have a capacity to refuel 75 fuel cell buses with 24 hours of operation per day (1.5 TPD). The project is expected to be operational soon with the first set of buses likely to be operational from the Gujarat refinery to iconic destinations in the state.

We are set to commission the 2G ethanol production plant at the Panipat refinery, based on indigenous R&D technology for production of 2.4 KLPD fuel grade ethanol. We have also entered into a strategic partnership with LanzaTech, USA, to commission the world’s first 3G ethanol production unit from refinery off-gas, based on gas fermentation at the Panipat refinery in 2021-22.

IndianOil’s first catalyst manufacturing plant is under construction at its Panipat refinery, where hydro treating catalyst for DHDT/DHDS and ZSM-5 additives for FCC/RFCC units will be produced.

Upcoming 2G Ethanol plant at Panipat

We continuously assess, identify and explore potential cases of mergers, acquisition, and partnership opportunities to accelerate growth. Our due diligence team conducts environmental evaluation, mega trend analysis, competitor analysis, supply–demand analysis, etc., to identify growth areas for the Company and synergies derived thereon, if any. Identified specific opportunities and complementary core competencies are then evaluated for jointly moving forward.

Our intellectual capital defines our way forward and provides ‘energy equity’ to India. We understand the dynamic and changing hydrocarbon landscape, aspiring to maximise innovation and create value for our customers. Collaborations with strategic partners allow us to explore new opportunities, creating a distinctive position for us to drive innovation across our products and processes.

Upcoming 2G Ethanol plant at Panipat

Start-up incubated by IndianOil adjudged Best Start-up of the Year 2020 under FIPI Awards 2020

Best Indigenously Developed Technology’ by Centre for High Technology (CHT), for IndianOil’s in- house AmyleMax®

The R&D team at IndianOil developed the INDMAX Fluid Catalytic Cracking (FCC) process technology to improve yield of light olefins / LPG and high-octane Gasoline from various petroleum residue/ heavy feedstock. We pioneered the country’s flagship technology that combined our proprietary INDMAX catalyst and processes with exclusive design features and know-how of our strategic partners. The patented technology was commercialised in 2003 at IndianOil’s Guwahati refinery with 100-kTA capacity unit. Steadily, the technology was installed at other key IndianOil refineries, currently offering a cumulative INDMAX capacity of 17.25 MMTPA. Besides captive use, INDMAX technology is also selected through global competitive bidding by NRL, in domestic merket for its 1.95 MMTPA unit at Numaligarh Refinery, Assam and also in foreign market, i. e., NIS Serbia for revamp of 660 KTA FCC unit at Pancevo refinery.