of crude processing

of petrochemical production

of pipeline network

IndianOil owns 9 refineries in strategic locations across India. Refineries consist of the most critical link to the supply chain of petroleum products, solely responsible for the production of several downstream products. To fulfil market demand for multiple products, the refineries have developed optimum production capacities.

Refining capacity

Capacity utilisation achieved in 2020-21

Market share of India’s total refining capacity

We intend to enhance our crude refining capacity from 70.05 MMT to 87.55 MMT by 2024-25, to meet the growing demand for petroleum products. Our continuous efforts to increase petrochemical production along with refining capacity expansion is expected to drive profitability in the days ahead.

proposed target of Petrochemical Intensity Index of IndianOil refineries

Except LPG, the demand for all petroleum products reduced due to the Covid-19 pandemic. However, processing of crude yields only 5-6% of LPG. This resulted in a rapid spurt of fuel stocks at refineries and pipeline product management had to be addressed through meticulous planning. Optimum throughput of LPG was maintained after making arrangements for adequate temporary storage, following strict safety measures.

IndianOil is the second largest producer of petrochemicals in India with integrated downstream facilities across its key refineries. The Linear Alkyl Benzene (LAB) plant at its Gujarat refinery, as well as the Paraxylene/Purified Terephthalic Acid (PX/PTA), Polypropylene Plant at Paradip Refinery and Naphtha Cracker Plants at its Panipat Refinery are state-of-the-art integrated units that strengthen our presence in the hydrocarbon value chain. Each of these world-class facilities are equipped with modern infrastructure and introduce new synergies of production.

Polymers

PTA

MEG

LAB

total petrochemical capacity

Product Application Development Centres (PADC) at Panipat and Paradip refineries

We are already developing 3.1 MMPTA additional capacity by 2024-25 with a capital outlay of ₹ 35,000 Crore. It is expected to aid the development of new grades of polymers and help to meet increasing demands from consumer and non-consumer durables sectors. It will also improve our market share and ensure sustained value creation in the coming years.

While logistic and supply chain disruptions caused temporary setbacks in operations, the team fought back to support the nation at a time of crisis. Biocompatibility and Drug Master File (DMF) approval for (poly propylene) PP grade 1200MC was obtained in record time. The 1200MC grade has since been established for medical devices and disposable syringes. We also introduced PP grade 1350YH, a niche product, to address emerging requirements of personal hygiene products like sanitary pads, diapers, face masks, etc.

IndianOil pioneered the oil pipelines network in the country and today, we manage and operate the largest oil pipeline network in India. Our more than 15,000 Km, cross-country pipeline network has been globally benchmarked as the safest, cost effective, energy efficient and environmentally friendly mode of transportation for crude oil and petroleum products. It is a firm testimony of our engineering brilliance that enables us to efficiently link key production and consumption sites across the country.

of throughput achieved in 2020-21

Transportation of EBMS through cross-country pipelines will now be accelerated. The use of LS-ATF as plug for aviation and non-aviation fuels will streamline operations with higher throughput. Pipeline projects valued over ₹ 24,963 Crore are under implementation on standalone basis, which upon completion, would increase the pipline network length to around 21,000 kms and capacity increased to 143.83 MMTPA and 49.5 MMSCMD respectively for liquid and gas pipelines.

Industrial Internet of Things (IIoT) based performance monitoring and predictive analysis system for forecasting health of critical assets (mainline pump, motor and VFD) was introduced during the year. It included several technologies for monitoring reliability, pilferage, maintenance and automation of the pipeline division. A centralised management system was also implemented to evaluate corrosion growth and risk assessment of the pipeline network.

Present (2021)

2025

2030

Note*: Through own and JVs

Aligned to the Government of India’s vision of increasing the nation’s share of natural gas in the primary energy mix to 15% by 2030, IndianOil is creating world-class infrastructure for natural gas pipelines, regasification terminals, and CGD infrastructure on standalone basis and through JVs.

of gas pipeline network (including JV’s)

of throughput achieved in 2020-21

PESO license obtained for LNG mobile dispensing at IndianOil’s R&D facility in Faridabad, aryana, a first-of-its-kind initiative for conducting trials of LNG as a fuel for heavy duty trucks.

of sales in 2020-21

B2B customers - (nine added in 2020-21)

Expansion of Ennore LNG Terminal capacity from 5 MMTPA to 10 MMTPA has been planned along with capacity booking at other upcoming terminals.

Auto-LNG dispensing stations to be set up by IndianOil across the Golden Quadrilateral and North–South National Highways of India by the end of 2021

Regasification terminals (in MMT)

We possess one of the largest petroleum marketing and distribution networks in Asia. Our pan India network of fuel stations, bulk storage terminals, inland depots, aviation fuel stations, LPG bottling plants and lube blending plants help to meet the energy needs of billions of Indians.

Terminals/ Depots

Aviation Fuel Stations

Lube blending plants in India

LPG bottling plants in India

LPG distributors (293 added in 2020-21)

Retail outlets (including KSK’s)

Consumer pumps across India

CNG stations across India

LPG bottling capacity (TMTPA)

beneficiaries of LPG under Pradhan Mantri Ujjawala Yojana, as on March 31, 2021

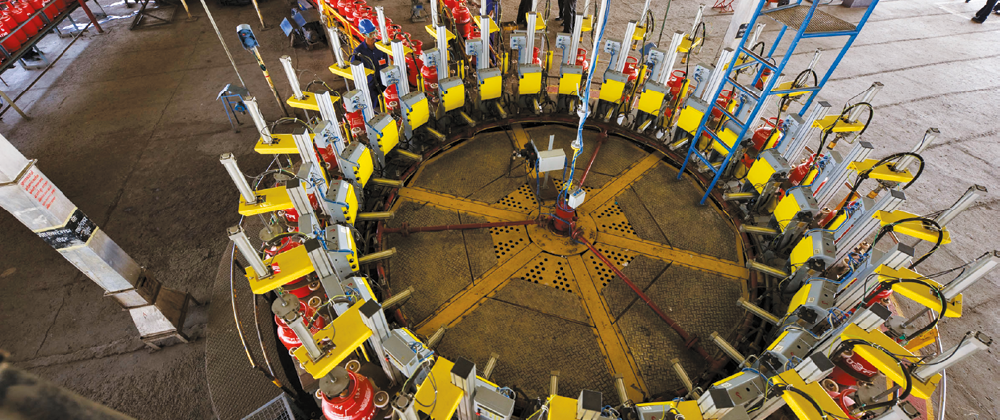

Earlier, LPG bottling plants had to be operated manually. Today, however, most operations are performed automatically, including the filling of LPG in cylinders. Installation of vision readers and downstream automatic check scales, valve-leak detection machines, integrated weight correction units and O-ring leak detection machines have enhanced the efficiency of our bottling units.

While the world grappled with a devastating pandemic, we remained focused on our objective to deliver LPG refills to customers without any interruptions.

Challenges:

Resilience

Despite odds, our team adopted methods to reach customers in the remotest corners and ensured steady supply of LPG across the country, even during the pandemic. We introduced Health Insurance Policy cover for delivery personnel, ensuring the health and safety of our people as well as their families.

refills achieved on April 30, 2021, the highest ever single day last mile delivery

Utilising the synergies of an integrated business model, we are pursuing growth opportunities in the upstream hydrocarbon value chain. In collaboration with strategic partners, we continue to expand our footprint in domestic and overseas markets. IndianOil plans to acquire E&P assets, preferably those that are producing or near-term producing assets worldwide, depending on their commercial viability. In addition, IndianOil actively scouts for prospective assets in India through open acreage licensing policy, discovered small field round, and abroad licensing rounds of other countries or domestic/overseas farm-in opportunities, either on its own or in association with other companies, to build a balanced portfolio of E&P assets.

IndianOil is a non-operating partner in Mukhaizna project in Oman

domestic upstream blocks

overseas foreign upstream blocks

production target by 2023-24

production target by 2029-30

IndianOil’s E&P business evaluates various upstream farm-in opportunities worldwide, from time to time, with sizeable liquid hydrocarbon reserves, low production costs and the possibility of bringing Equity Oil to India.

IndianOil has a thriving Cryogenics business with expertise in design & production of state-of-the-art vacuum super-insulated cryogenic storage and transport vessels. We are one of the largest manufacturers of cryogenic containers in the country. A market leader with nearly four decades of experience in cryogenic and vacuum engineering, we serve various industries like Refineries, Chemicals, Aviation, Lubricants, Animal Husbandry, Gas etc., through specialised and custom-built product lines.

The Cryogenics Group sold over 30000 cryo cans during 2020-21. The group also sold highest number of refuellers, Aviation containerised tanks with module and customised heavy duty refuellers during the year.

Al Nuaman LNG Tanker

IndianOil is the pioneer and largest provider of bulk Explosives and blast based services in country. A commitment to innovation and technology is driving differentiation in key mining sectors. Since 2014-15, the production and sales of bulk explosives has grown by 165%. Various cost optimisation measures introduced during the year resulted in increase in the margins.