Our R&D Centre serves as the bedrock of our strategy and future growth prospects. The year under review has been a year of many achievements. The relentless pursuit of innovation, countless hours of lab work and unstinted faith in the power of possibilities have driven our growth.

Despite the challenges posed by the pandemic, we crossed a huge milestone — 225 patents, the highest number of patents filed in a year in IndianOil’s history, out of which 155 were granted. As on March 31, 2022, we have a portfolio of 1,519 patents with 1,410 effective patents, double as compared to 2017-18.

Our R&D focus continues to revolve around our core areas of expertise which include fuels and lubricants, refining technologies and catalysts, petrochemical and polymers. We are also diversifying into emerging sectors such as nano technology, solar, bioenergy, hydrogen, fuel cell, and energy storage.

Our aim is to develop cost-effective, environmentally and socially responsible technology solutions. With the Government of India’s thrust towards ‘Make in India’ and ‘Aatmanirbhar Bharat’, we have been developing technologies and solutions across multiple target segments, especially in competitive and licensor-controlled areas dominated by MNCs.

We are also diversifying into emerging sectors such as nano technology, solar, bio-energy, hydrogen, fuel cell, and energy storage.

Successfully commercialised XTRAFLO indigenous Drag Reducing Additives (DRA) technology, resulting in significant cost savings. The performance of in-house developed DRA in crude as well as product found at par with commercial products.

Successfully completed performance guarantee test runs for 1.2 MMTPA grassroot indeDiesel®s unit at Haldia Refinery for BS-VI Diesel and 35 KTA grass-root INDAdeptG unit at Guwahati refinery for BS VI gasoline production.

Supported the country’s Defence forces by developing and producing Winter grade BS-VI diesel at Panipat Refinery meeting IS1460-17 and Army Grade DHPP (Winter Grade) specifications.

Servo Pride XL Plus 5W-40 is cleared for K9 Vajra high altitude application (Artillery Guns – Engine ATU and Final Drive Units) and Servosynco E46 got approval by the Ordnance factory, Medak (Telangana) in Ingersoll Rand Make compressor in hull machine shop.

With the endeavour to develop long life, energy efficient lubricants and greases that addresses customers’ needs as well as serves as an import substitution, 135 lubricant formulations were issued and approvals from 68 major global OEMs was obtained.

Developed eco-friendly engine oils such as ‘SERVO Greenmile 5W-30’ for passenger cars and ‘SERVO Raftaar 15W-40’ for commercial vehicle segment, with distinguished friction and oxidation properties in BS-VI vehicles.

A new genre of ‘Mixed Metal Oxide’ isomerisation catalyst developed in collaboration with M/s Viridis Chemicals and planned for demonstration at Bongaigaon Refinery in 2023.

A high temperature oxidation stability test developed to assess oxidation stability of engine oils of API SM, SN and CJ-4 performance levels at elevated operating temperatures.

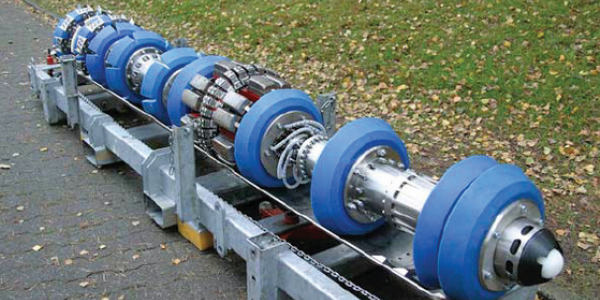

Developed an in-house 28-inch inline inspection tool (IPIG) based on Magnetic Flux Leakage (MFL) technology for our Pipelines Division.

Developed and launched ‘IndianOil XTRAGUARD’ surface disinfectant spray with silver nano particles dispersed in Hydrogel. The patented product is a first-of-its-kind nanobased healthcare product.

We continue to make steady progress in our digital transformation journey. During the year under review, the launch of our project ePIC – e-Platform for Customers, proved to be a game changer. We have built a platform that integrates all the end customers across different lines of business under one roof. This has empowered us to increase the overall efficiency of our processes and maximising the value creation for all stakeholders by automating various processes such as KYC, multi-channel LPG refill booking, payments, invoicing, and loyalty programmes management.

We also provided an interface for rolling out customercentric welfare schemes of GoI such as PMUY 2.0 and PMGKY. Additionally, we utilised SAP S/4 HANA (IS-Utilities) to strengthen our foray into CGD business by onboarding of more than fifty thousand customers during the year.

During the year, we continued to work towards digitising our operations through measures such as implementation of paperless offices, vendor invoice management and document management systems. We have also strengthened our Enterprise-wide Unified Digital Business Ecosystem to address the pandemic-induced challenges and ensured seamless supply of products and services to customers across the country. Alongside of deploying new technologies and platforms, we also strengthened our IT security measures to ensure robust data privacy and security.

We have also rolled out an Integrated Transaction Processing Server (ITPS) solution at major retail outlets for providing fidelity of actual sales with payment and loyalty. This ensures delivery of e-receipts, platform for providing service rating and earn loyalty points (XTRAREWARDS Points) against the transaction in a seamless manner.

Another landmark project — End-to-End Project Management Suite (E2EPMS) was rolled out during the year. It is a digital dashboard with comprehensive project management and monitoring abilities to track project life cycles of all volume ranges, facilitating easy, on-the-go, and dynamic project progress status and updates to all concerned stakeholders.

CGD customers data integrated in our system through SAP S/4 HANA (IS-Utilities)

Retail outlets having ITPS solution

With rapid advancement in digital technologies, the quality control department of marketing division has taken up the initiative of converting all the labs to smart labs in a phased manner. This upgradation is expected to derive the following benefits:

Marketing labs upgraded to the status of a smart lab in 2021-22

Total smart labs as on March 31, 2022

With the aim to further expand our footprint and facilitate transformation as an integrated energy major, IndianOil is setting up a second R&D facility in Faridabad — IndianOil Technology Development and Deployment Centre. The facility is going to be the world’s largest net-zero (power and water) facility with a GRIHA-5-star rating, LEED platinum standards and consisting of many new research centres of excellence in areas of alternative and renewable energy, corrosion research, nanotechnology and synthetic biology. It is expected to be commissioned in 2023-24.

Going forward, we will also focus on building a complete digital business ecosystem that is convenient, efficient, automated, delivery-centric, agile and fully secured. The ecosystem will encapsulate a full-fledged e-Commerce portal including notfor-retail products and service herein all line of businesses can be integrated, and all stakeholders can be provided with a unified and seamless experience.

The ISO 17025 accreditation is one of the most important standards for testing and calibration of laboratories around the world. Additionally, NABL accreditation is mandatory for all laboratories for ensuring accuracy of the test results released by any laboratory. 51 quality control laboratories in marketing division have been accredited by National Accreditation Board for Testing and Calibration Laboratories (NABL) as per International Standard ISO/IEC 17025: 2017 for ‘Testing Discipline’ while 3 laboratories are accredited by NABL for ‘Calibration Discipline’.