We have implemented several business practices that are focused on enhancing our environmental performance such as reduction of GHG emissions, greener fuel, green building, energy efficiency, water conservation and many more. We are also working towards various initiatives such as wasteto-value, which uses waste plastic, used cooking oil, and other materials to generate fuels directly.

We strive to reduce the negative impact on our climate. We have also taken all the required steps to manage and reduce the GHG emissions caused by our operations. In addition, fuel quality upgradation project helps us reduce SOX emissions to the environment. Sustainable development initiatives such as rainwater harvesting, water, carbon and waste footprint mapping, installation of solar panels, LED light and tree plantations are some of the efforts taken by us to reduce our carbon footprint.

Launch of XTRAGREEN XTRAGREEN was launched by IndianOil, which reduces emissions and improves fuel economy by 5.78%.

We have taken ambitious targets to realise our vision of being carbon neutral, internalising circular economy on water and waste management and being a benchmark in the energy sector.

Energy management is one of our main focus areas, as it has direct impact on the overall business operations. We are constantly working towards the use of cleaner energy sources such as bioenergy, green hydrogen, plastic to fuel that support our efforts of reducing our carbon footprint. The various governments initiatives and the Production-Linked Incentive (PLI) scheme foster our efforts to move towards clean and sustainable energy sources. Moreover, energy management system (EMS) is implemented to optimise energy consumption.

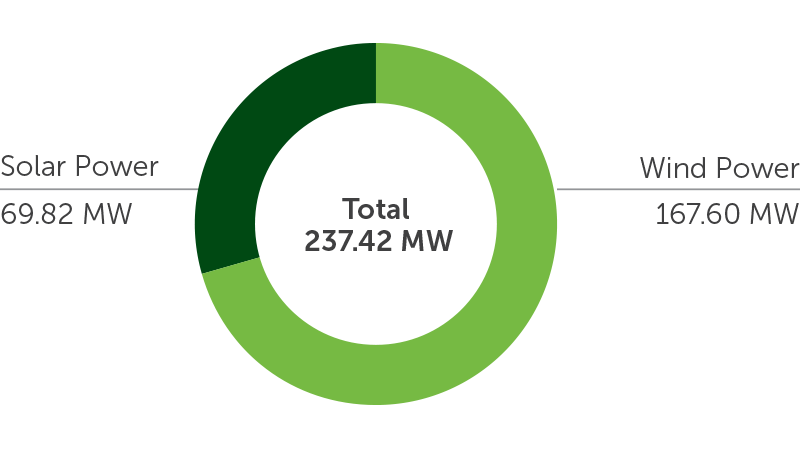

Total Installed Capacity (till 31.03.2022)

Total energy consumption

Energy conservation schemes implemented

Green hydrogen production capacity

We are actively promoting the adoption of green power by our retail network. Our 1,166 outlets implemented solar energy in their operations. As on April 1, 2022, our outlets have a total installed capacity of 111.5 MW and an annual energy generating potential of 118 million units of solar power.

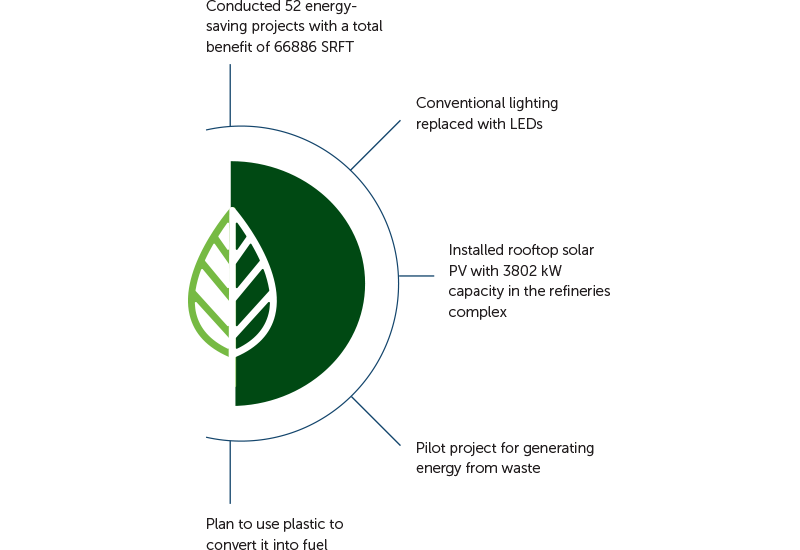

IndianOil took the following initiatives to be energy efficient and transform our organisation into a green campus:

Our robust water management strategy focuses on measuring water withdrawals and consumption, as well as taking initiatives to raise water efficiency in our operations. We ensure ‘Zero liquid Discharge’ from our operations. We also undertake rainwater harvesting at our facilities to ensure the optimal use of water.

We carrried out a water consumption study for all our refineries to understand the water consumption patterns and watersaving potential. Monthly water audits are also conducted to periodically monitor consumption patterns. Moreover, refineries have internal MoUs that include indicators such as specific freshwater consumption, percentage of reuse, and specific discharge that are monitored, and real achievements are examined monthly during performance review meetings with the top management, and annual targets are revised with strict targets.

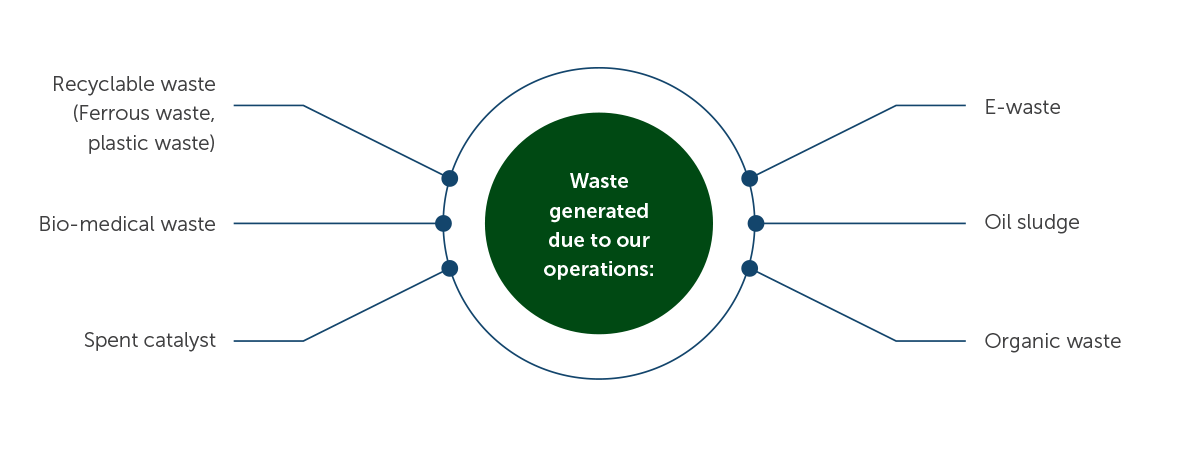

At IndianOil, we ensure that efficient waste management practices are in place. We follow laws and policies implemented by statutory bodies including State Pollution Control Boards (SPCBs). We are responsibly taking all the steps, which involve identifying and diverting waste generated by our operations. We have initiated relevant measures for waste reduction, recycling and efficient waste treatment. IndianOil is working in the realm of waste-to-value, using plastic waste, and used cooking oil to make fuels.

Refineries are the main source of hazardous waste generation including oily sludge and spent catalyst. Oily sludge gets generated during storage tank bottom cleaning and ETP operation. In 2021-22, 1.17 lakh MT sludge disposal was done by processing in Delayed Coker Unit (DCU), Sludge Processing Unit, Confined Bio-remediation and On-site bio-remediation.

Similarly, spent catalyst and adsorbents are generated in substantial quantities in refineries and petrochemicals units. Spent catalyst disposal is done as per nature of catalyst. During the year, about 8,933 MT of spent catalyst was recycled safely disposed through authorised Treatment, Storage, and Disposal Facilities (TSDFs), e-auction to authorised metal recyclers and authorised coprocessors of RFCC spent catalyst. Waste disposable practise by IndianOil is mentioned below:

Under the Corporate Environment Responsibility (CER) Scheme, IndianOil undertook first-of-its-kind project — protection of Olive Ridley turtles – in collaboration with the Wildlife Department of Chennai. Olive Ridley turtle eats invertebrates and is considered to play a vital role in both open ocean and coastal ecosystems. Through the initiative, hatchlings of the turtles were released into the sea.