Energy conservation is a vital component in our journey towards a sustainable and greener future. By adopting energy-efficient practices and embracing renewable energy sources, we can significantly reduce our carbon footprint, conserve natural resources, and create a cleaner and healthier environment for future generations.

In 2022-23, 119 energy conservation schemes (in-house, PCRA-identified and EIL-identified) were implemented across the refineries, helping achieve energy savings of 2,55,379 SRFT/yr, equivalent to monetary savings of H 840 Crore/yr. In total, approximately 0.81 MMT equivalent CO2 emission per year was achieved.

From rooftop solar installations to innovative indoor solar cooking systems and pilot trials of alternative fuel blend, IndianOil is actively contributing towards a circular economy, with an emphasis on a greener future.

Adopting Renewable Energy

At Paradip Refinery, a significant step has been taken towards renewable energy adoption with the installation of 1.87 MW capacity solar panels over the roof of the warehouse. This solar power generation facility helps reduce the reliance on conventional power sources and promotes the use of clean energy. Moreover, at the IndianOil Bulk Explosives Plant in Umrer, Nagpur, a 13 kW off-grid solar power project with battery backup has been completed. This project caters to the entire electrical load of the administrative building, further emphasising IndianOil’s commitment to sustainable energy solutions.

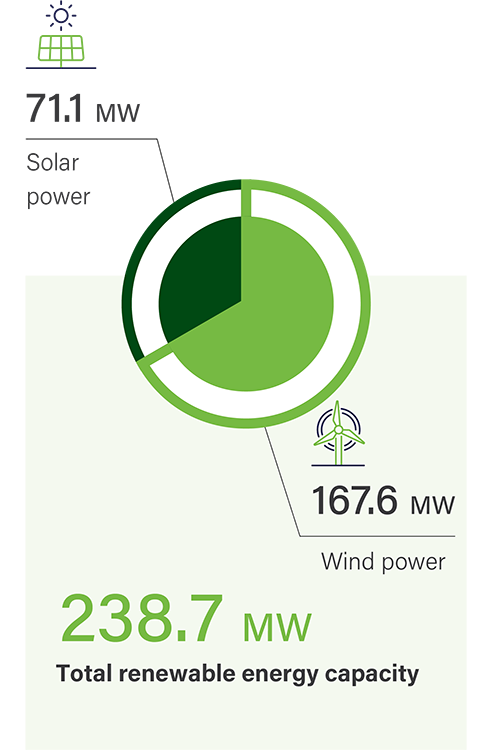

In addition, we are actively contributing to the renewable energy sector with our current renewable energy capacity of 238.7 MW. Through a recent collaboration with NTPC Green Energy Limited, we are poised to significantly augment our renewable energy capacity by approximately 2 GW.

Moreover, at the IndianOil Bulk Explosives Plant in Umrer, Nagpur, a 13 kW off-grid solar power project with battery backup has been completed.

Indoor Solar Cooking System

Our R&D Centre has developed an innovative indoor solar cooking system - a stationary, rechargeable, cooking solution that caters to the needs of Indian households.

Currently, 50 units of the Solar Cooktop have been deployed for pilot trials across five different cities in India, including Leh, Lakshadweep, Gwalior, Udaipur, and Delhi-NCR. The trials, which consider solar radiation intensity and cooking habits, are currently in progress. Moreover, IndianOil has collaborated startin with 10 Indian vendors for the manufacturing, marketing, installation,

and after-sales service of the product. By leveraging economies of scale, raising product awareness, government support, and suitable financing mechanisms, IndianOil aims for the successful rollout of the Solar cooktops in the market.

IndianOil’s commitment to renewable energy is further exemplified by the recent unveiling of a double cooktop variant of the indoor solar cooking solution during the Indian Energy Week 2023, graced by the Honourable Prime Minister.

IndianOil has collaborated with 10 Indian vendors for the manufacturing, marketing, installation, and after-sales service of Solar Cooktop.