Environment Management

Health, Safety & Environment: The three pillars to ensure safe communities and happy stakeholders

At IndianOil, we believe that it is possible to fuel the energy needs of the Nation while also protecting people and the environment. We are committed to conducting business in a manner that is compatible with the environmental and economic needs of the communities in which we operate, and that protects the safety and health of our employees, those involved with our operations, our customers and the public.

IndianOil accords topmost priority to conducting its business with a strong environment conscience, ensuring sustainable development, safe workplaces and enrichment of the quality of life of its employees, customers and community at large. All refineries are certified to ISO:14064 standards for sustainable development as well as for the Occupational Health & Safety Management System (OHSMS/OHSAS018001), besides having fully equipped occupational health centres. Compliance with safety systems, procedures and environment laws I monitored at the unit, division and corporate levels.

As India's leading oil & gas corporate, IndianOil remains steadfast in its commitment to excellence in Safety, Health and Environmental (S,H&E) performance. This publication showcases how IndianOil People are relentlessly pursuing multiple commitments at the operations, social and environmental levels to fully realize IndianOil's potential as the prime mover of a resurgent India.

Environment Management at IndianOil

In the course of refinery operations, waste water, flue gases, fugitive emissions and solid wastes are generated. Refineries are also significant consumers of scarce resources like water and energy. Thus, pollution control and resource conservation activities are a priority area for environment management at IndianOil. Effective treatment of wastewater and recycling, energy conservation and pollution abatement are examples of integrated activities that result in both pollution control and resource conservation.

Our installations including refinery units continuously strive to :

- Minimize adverse environmental impact from refinery activities, products and services by using processes, practices, materials that avoid, reduce or control pollution;

- Conserve scarce natural resources by continually optimizing their consumption.

Pollution Control and Resource Conservation

The different aspects of Environment Management in IndianOil are detailed below :

Waste Water Management

Use of water and quality of effluent discharged are carefully monitored. Our refineries are equipped with a network of underground sewers for segregated collection of various wastewater streams, which are subjected to precise treatment in well-designed effluent treatment (ETP) facilities involving physical, chemical and biological processes.

State of art equipment have been provided in the ETPs like Tilted Plate Interceptor (TPI), Dissolved Air Floatation (DAF), Bio-tower, activated sludge basins, dual media filters for treating oily wastewater and hydrogen peroxide / wet air oxidation treatment for spent caustic streams etc. These treatment facilities are backed by sophisticated instrumentation and real time monitoring systems for close and precise monitoring. In Marketing and Pipeline locations, effluent water is routed through oil water separator.

Water Conservation

- Treated effluent streams are reused / recycled for various purposes in refineries like make-up for fire water, cooling tower, coke cutting in Delayed Cokers, etc.

- Sour water generated in various units is stripped of contaminants such as ammonia and H2S and recycled in de-salters besides using it for process flushing requirements.

- Advanced treatment systems like Ultra Filtration, Reverse Osmosis etc. are used to convert treated effluent to de-mineralised water or for use in cooling towers as make-up water.

- Advanced treatment systems like Ultra Filtration, Reverse Osmosis etc. are used to convert treated effluent to de-mineralised water or for use in cooling towers as make-up water.

All these steps have led to 80-95% wastewater being reused in our refineries, which has resulted in substantial reduction in fresh water consumption.

Prevention of Air Pollution

Utmost attention is given to control / reduce emissions in our refineries. Major sources of air emissions are flue gases from boilers and heaters, FCC regenerators and Sulphur Recovery Units. Hydrocarbon leaks and evaporation during storage, handling and transportation of petroleum products and crude oil are sources of fugitive emissions. IndianOil has adopted the following measures to control emissions & effectively disperse pollution from flue gases.

- Tall stacks for effective dispersion of pollutants.

- Use of low sulphur fuel oil/ sweet natural gas/ de-sulphurised refinery off-gas in boilers and heaters to minimize SO2 emission.

- Use of low NOx burners.

- Hydrogen Sulphide in different refinery process units is converted to elemental sulphur in Sulphur Recovery Units.

- Sulphur dioxide emissions from Catalytic Crackers are controlled by effective feed sulphur management.

- Flue gas scrubbing at FCC units at Haldia & Barauni Refineries for arresting emission of sulphur dioxide and particulate matters.

- Carbon monoxide from FCCU regenerator is incinerated in CO Boilers and the resultant energy is utilized for steam generation.

- Use of floating roof tanks for crude and other light product services & Mechanical seals in pumps for minimizing fugitive emission of hydrocarbons.

- Use of closed blow down vessels & safety release to flare system for arresting any emission of hydrocarbons during all situations, normal, abnormal as well as emergencies.

- Continuous reduction in fuel consumption by ENCON measures, heat integration and increased use of hot feed in downstream processing units.

- Flare gas recovery systems.

For careful monitoring of emissions, continuous online analyzers have been installed in all the refinery stacks. On-line connectivity is also being provided to Central and State Pollution Control Boards.

Mobile vans and fixed monitoring stations equipped with sophisticated instruments for monitoring ambient air quality have also been provided in our refineries. In Marketing installations, all vehicles under contract are required to have Pollution Under Control certificates that are checked routinely.

Air Quality Management

Solid Waste Management

Prevent, Reduce, Reuse and Recover are the fundamental principles that govern all our activities, more so in case of solid waste management. Oily / chemical / biological sludge generated from storage tanks during refinery turnarounds or from the basins & storage tanks of our effluent treatment facilities are mechanically handled. Melting pits with skimming pumps, sophisticated hydro-cyclones, centrifuges etc. are employed for de-oiling the sludge.

After de-oiling, residual sludge is recycled in Coker units or bio-remediated in well-designed environmentally safe sites. Bio-remediation in confined bioreactor is the latest innovation in bio-remediation of residual oily sludge (as shown in the picture below), developed in-house by IndianOil R&D. Called Oilivorous-S, this environmentally safe and clean technique was called to the fore to manage the oil spill at Ennore near Chennai in Jan-Feb. 2017, validating IndianOil's focus on environment protection.

Spent catalyst that contains recoverable metals is sold to authorised recyclers, including cement manufacturing facilities approved by the SPCB and producers of refractories, ceramics, and other materials. Spent catalysts that cannot be recycled are either given to approved Treatment, Storage, and Disposal Facilities (TSDF) or kept at designated common hazardous waste disposal sites.

IndianOil follows the E-Waste Management and Handling Rules, 2010 and any revisions. The E-waste is sold to authorised recyclers or collected under repurchase agreements by equipment providers.

Across IndianOil locations, organic waste is either converted into compost and/or biogas through use of biogas or organic waste converter units. There are 100+ functioning units across IndianOil locations. In other locations, these are disposed in secured landfills.

Paper waste is sold to designated recyclers. Some offices have been connected to recyclers who offer stationary in return for sale of paper waste.

As a petrochemical provider, IndianOil has been given Extended Producer Responsibility to undertake recycling of plastic waste. The company is undertaking efforts for segregation and upcycling of plastic waste, developing process fuels and use in road making. To know more, refer to the section on Circular Economy.

Recyclable wastes such as metal, rubber, etc., are stored in scrapyards before being sold to SPCB authorised recyclers.

Oil Spill Response (OSR) Facilities

Accidental oil spills, whether on land or water (including both sea and fresh water) have the potential to cause serious problems for coastal and marine wildlife, especially corals, fishes, birds, mammals and reptiles.

IndianOil business largely depends on crude imports through VLCC and other tankers which are unloaded through single buoy mooring (SBM) systems. Thus concern for marine life ensures that IndianOil has a well-structured system in place to plug / handle all possible sources of oil leaks including oil tanker spills, non-tanker ship spills, pipelines from SBM to onshore tanks and tank farms or may be cross country crude oil and product pipelines.

IndianOil's Tiered Preparedness and Response enables a structured approach to both establishing oil spill preparedness and undertaking a response. It helps categorise potential oil spill incidents in terms of their potential severity and the capabilities that need to be in place to respond.

Considering the regulatory framework under which this offshore marine oil spill is managed, other than the Environment Protection Act-1986 which is the basic act for all environmental activities in India, the most important and direct help comes from the National Oil Spill Disaster Contingency Plan briefly known as NOS-DCP. The NOS-DCP is the only national plan dealing with oil spill response, which delineates the responsibilities of various resources. Indian Coast Guard is the nodal agency for NOS-DCP (for handling the oil spill in Indian waters).

Noise Pollution Control

Major sources of noise pollution are engines, compressor house, turbine hall, furnace etc. IndianOil's units and installations have adopted following measures to control noise at source.

- Regular maintenance of machines

- Use of low noise machines

- Suitably designed enclosure for both source and receiver

- Use of sound absorbing material

Personnel Protective Equipment (PPEs) like ear plugs, earmuffs, etc. are also used in identified high noise areas.

Green Belts and Ecological Parks

IndianOil regards ecological and environmental protection as the focal point of our environmental conservation programmes. To give back to the nature, the company undertakes large-scale plantations across locations. Approximately 40 lakh trees are estimated to be surviving within & beyond boundary

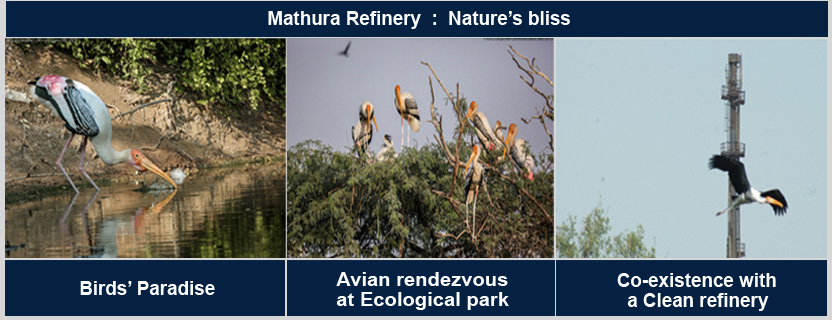

At IndianOil, we have regarded ecosystem protection and tree plantation as fundamental to our environmental conservation programmes. The Company’s scientifically designed green belts spread across the country, serve as a pollution sink besides enhancing the aesthetics of the area. The green spaces are teeming with flora and fauna.

Flourishing eco-parks with acres of green spaces in IndianOil locations have become mini bird sanctuaries, which serve as a bio-indicator and stand testimony to the fact that industry and ecology can co-exist in harmony. During the monsoon season, birds rush to nest in large spaces of green-belts and eco-parks. More than 300 species of resident and migratory birds thrive in the Eco Parks and Green belt areas of the company.

Coral reefs are a great indicator of underwater biodiversity. The reefs are under significant threat due to climate change and pollution. The coral reefs off-shore at Gujarat have been identified as being particularly vulnerable to these threats. With the requirement to change the four-decade old pipelines laid offshore in Vadinar, Gujarat, IndianOil undertook a challenging task of trans-locating the corals with minimal impact on sensitive ecosystem. The project was successfully completed with the help of Zoological Survey of India.

The eastern coast of India is prone to cyclonic storms which are a great threat to humans and other flora & fauna. In FY 2021-22, 20 lakh+ saplings were planted in a land area spanning 122 hectares at Beliarichar island and at Balughata and Rairaychak Mauza in the District of Purba Medinipur with the help of Forest Department, Govt. of West Bengal. The plantations include Mangroves and Casuarinas which help break high cyclonic wind-speeds, thus helping in protecting the coastal ecosystem. Further, as a green initiative, e-portals have been launched and payments, data transfer are done using the electronic media. This results in considerable saving of paper, thereby preventing cutting of trees.

Energy Efficient Petroleum Refining

Energy conservation is at the heart of IndianOil's decision regarding technology selection for refinery processes and its operation cycles. Improvements have been made possible through implementation of various energy conservation measures coupled with operational improvement by adopting advanced technology and best operating practices.

Since 2010, benchmarking studies are carried out once every two years under the aegis of Centre for High Technology (CHT), MoP&NG to rank performance of IndianOil Refineries with peer groups and the best in the class refineries worldwide. Identified gaps are bridged through implementation of suitable ENCON (Energy Conservation) measures.

In addition, profitability improvement and optimisation studies are regularly carried out by external agencies such as KBC, Mckinsey, NTPC, etc. as well as by in-house Process Design and Engineering Cell (PDEC) of IOC.

Auto Fuels Quality Improvement

IndianOil has progressively upgraded quality of auto fuels in terms of emission related parameters and to meet the quality requirement of new generation vehicles. Our refineries have implemented various projects for meeting this objective.

Past few years have seen a rise in green innovation and increasing importance of capital investment in green projects, with India being rated as one of the most attractive country for green project investments.

Green fuel initiatives of IndianOil started in 1990s and auto fuels quality has been progressively upgraded in terms of emission related parameters and to meet the quality requirements of new generation vehicles. Between 2000 and 2010, an investment of approx. Rs. 20,000 crore was made on various fuel quality up-gradation projects in IndianOil refineries. Besides, IndianOil has met the challenging deadline of making available 100% BS-VI quality auto fuels by 1st April 2020. For this, the Corporation has invested approx. Rs. 15,400 crore in major refinery upgrades, changes in supply logistics and other related transitions.

In addition, we are also working to emerge as a major player in Natural Gas business which is a less polluting fuel. We are targeting quantum growth in LNG imports, infrastructure and marketing, besides taking up city gas distribution to replace other polluting fuels in these cities. Natural gas is being supplied to industrial, commercial, transport and domestic consumers. Also, sale of Auto LPG has considerably increased over the years.

Fuelling India's Green Energy Quest

IndianOil is steadily progressing towards harnessing renewable energy to minimize carbon emissions for a green economy. Current renewable energy capacity stands close to 240 MW (about 5% of Total Electricity Consumption), comprising of 170 MW of wind power and 70 MW of solar power.

IndianOil has installed rainwater harvesting (RWH) systems and watershed projects throughout its locations and townships to cater to freshwater demand and recharge groundwater. The addition of refinery watershed projects has helped increase the volumes of rainwater gathered. From a catchment area of more than 2,800 Ha, the rainwater collecting structures have collected 7.46 billion litres of rainwater in FY 2021-22. This is equal to about 8% of IndianOil’s present freshwater consumption.

Towards decarbonization efforts, our biofuel avenues shall include Compressed Bio-gas, Sustainable Aviation Fuel (SAF), Bio-Diesel, Ethanol among others. We have also increased our emphasis on bio-energy and renewables. IndianOil has awarded 2188 LOIs for 5 MMTPA CBG production capacity under the ambitious SATAT (Sustainable Alternative Towards Affordable Transportation) scheme on CBG (Compressed Biogas). Marketing of CBG has commenced from 16 plants through 28 retail stores spread across nine states. We have also begun producing biofuels from used cooking oil and other non-edible oils for use in diesel blends.